How to Break In Your ATV Belt

Easy does it

There are plenty of parts that make up your ATV that we tend not to think about until they fail. Sure, we think about checking the oil and other fluids and cleaning the air filter sometimes, but one big issue we all run into at some point is: what do we do when a belt fails?

Many ATVs use a CVT transmission that uses a rubber belt as part of the powertrain, and in these rigs, a busted belt is a surefire recipe for a fistful of no-go and a stretch of irritating downtime. We’ve already covered the common causes of ATV belt failure – and how you break in your belt is a key step in preventing many of them.

Failing to properly break in a new belt can significantly shorten its life, so spending a few minutes on that task after installation can save you a world of headaches (and money) later. We’ve partnered with Gates to get their tips on how to break in a new belt, so you don’t break it.

Have Patience

The fastest way to wreck a new belt is to simply install the thing and take off wide-open. Brand-new belts need a moment, or three, to acclimate to their new duty and settle into the groove (pun very much intended). This is one instance in which a dose of patience can go a long way.

And yes, these steps can be done trailside with the spare belt you brought along. It may sting a little that you will have to take the time while trying to have a fun ride, but in the end, it is way better for you, your machine, and your sanity.

Find the Correct Belt for Your Machine

It may sound simplistic to remind you that you need to make sure to choose the right belt. But even one that’s just slightly out of OE spec can cause wildly unpredictable performance and odd behavior. That’s why Gates deploys a proprietary laser measuring system when producing replacement belts, assuring a perfect fit for your vehicle.

If your belt is worn, and you should check this at regular intervals along with other maintenance, then replace it at home and go through these steps. It is better to have a new Gates belt installed and broken in, and use the old worn out belt as an emergency replacement.

Go with a Gates

You may have heard that it is better to always go with a stock OEM replacement belt over an aftermarket one. With some products that might be good advice. Gates is the industry leader in belt technology, so there is no need to worry about replacing your worn-out stocker with a Gates belt. You will get a stronger belt that is longer lasting and can better handle the abuse a CVT transmission dishes out to the belt system.

If you are replacing the belt on a machine with an engine in the 800cc class or below, the new G-Force Workhorse belt is the way to go. It has a higher operating temperature threshold at 300 degrees (Fahrenheit), and it carries 20-percent more load than a stock belt. This offers you a longer lifespan for use over a stocker, or even previous G-Force belts - with proper break-in!

The Gates G-Force Redline belts are perfect for 800-class machines on up and are suited perfectly for high performance machines. It handles the heat and load better than any other belt for these types of machines, and will keep you on the trail longer – again, with proper break-in.

Gates even states on its website – don’t break it, break it in! The Redline and Workhorse belts outperform the stock belt in every category. That’s pretty impressive if you ask us.

Handle With Care

CVT belts, like Gates’s G-Force Workhorse or G-Force RedLine series, are extremely durable - when handled correctly. Bending, crimping or twisting your new belt creates damage to the tensile cords, creating invisible crimps that can lead to belt breakage. We’re not saying you need to handle your belt with kid gloves, but use common sense and don’t invert or backbend it before installing.

Image by stockphoto mania/Shutterstock.com

Clean Your Clutches

So you’ve purchased the right belt, and you haven’t been using it as a dog toy. Good work. Now you’ll need to make sure to clean your clutches to remove any dirt, debris, oils or leftover residue from your old belt, since these contaminants can lead to belt slippage and a noticeable drop in performance.

The easiest way to do this is by using compressed air to blow out dust and dirt, then by wiping the clutch sheaves clean using alcohol or acetone on a rag or mild abrasive, such as a general purpose hand pad. Just remember: don’t spray anything directly onto the clutches, or use a cleaner that’s intended for something other than clutches, like brake cleaner.

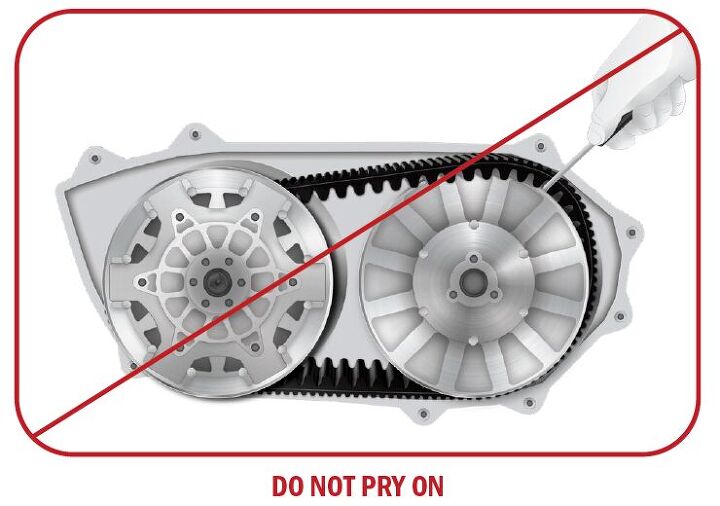

Install It (Properly)

Remember that list of common belt failures? Improper installation was at the root of a number of easily preventable issues. So be sure to follow any and all instructions – for instance, if you’re installing either of the G-Force belts, that means putting it on with the right side up (so the lettering is facing you). But above all, take your time, and take it to a pro if you don’t know what you’re doing.

Perform a Heat Cycle

Once the new belt is on your machine, it is critically important to put it through a couple of heat cycles in order to properly break it in. During your first drive after belt replacement, take the belt up to operating temperature by running the rig in high gear for about 15 or 20 minutes. Be sure not to exceed three-quarter throttle at this point and vary your speed between 20 and 45 mph. (Yeah, we know – that’s a tough ask for us, too.)

If the air temperature is especially frigid, as it often is during winter, plan to add 5-10 minutes to your drive. After this, park the machine and let it cool down with the motor off for about half an hour.

Pro tip: use this time to clean up the mess you just made in the garage while installing your new belt. If you’re trailside, take the time to enjoy a legal beverage and some good laughs with your buddies, who surely stayed around to make sure you got going again and not to rib you for breaking a belt. They wouldn’t do that, right?

Do It All Over Again

Be sure to run your ATV through another driving sequence like the one described above, making for a pair of break-in trips lasting about 20 minutes each. This double dose of caution will ensure a thorough break-in and help extend your new belt’s life right off the bat. Then let the vehicle rest for another half hour after this second cycle before giving it the beans on an open trail.

Image by stockphoto mania/Shutterstock.com

Why are we doing this break-in work? Rubber belts need to precisely match the pulley sheave angle in order to optimize power transfer and carry load. Otherwise, you’ll end up with a belt that slips more than a Southern driver after a rare ice storm. A belt that’s improperly broken in may not seat properly in the sheave, leaving small voids of space between it and the pulley. This can cause slippage and that aforementioned premature failure.

Gates G-Force RedLine and Workhorse belts have been proven to last up to three times as long as belts from competing brands when properly installed and broken in—meaning that sticking to the above steps can save you time, hassle and money down the road.

To learn more about Gates G-Force Workhorse and RedLine series, click here, then visit Navigates.Gates.com to find the right Gates belt for your vehicle.

NOTE: This is sponsored content produced in partnership with Gates

More by Sponsored Post

![Don't Try This at Home: Muddy Crash [video]](https://cdn-fastly.atv.com/media/2022/10/24/8744120/don-t-try-this-at-home-muddy-crash-video.jpg?size=350x220)

Comments

Join the conversation